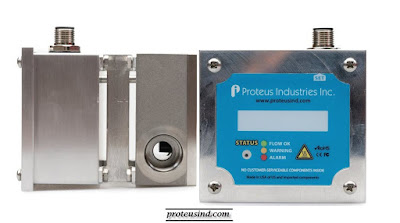

Compact Liquid Flow Control Valves - Proteus Industries Inc

Compact Liquid Flow Control Valves providing precise, programmable management of liquid distribution. FLC700 Series Flow Controller > Flow controller integrates valve, meter and display > Flow ranges from 5–100 LPM / 1.3–26.4 GPM > Programmable PID controller for precise control > Digital display > Analog output > Two programmable alarm levels > Usable to 60 °C / 140 °F and 0.4 MPa / 58 psi More DETAILS FLC600 Series Flow Controller > Stand-alone and built-in manifold versions available > Flow controller integrates valve, meter and display > Flow ranges from 0.5–20 LPM / 0.13–5.3 GPM > Programmable PID controller for precise control > Digital display > Analog output > Two programmable alarm levels > Usable to 60 °C / 140 °F and 0.4 MPa / 58 psi More DETAILS FCV-M Series Flow Control Valve > Direct control of flow or temperature from your PID controller with 4–20 mA, 1–5 VDC or 1–10 VDC ...